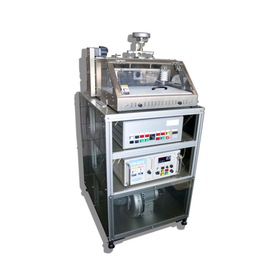

Easy implementation to visualize the history of factory equipment [Equipment Operation Monitor]

Real-time monitoring of factory equipment and site conditions! Achieving overall operational rate monitoring, anomaly detection, maintenance management, production management, and analysis tasks.

This is a web application that allows for easy and inexpensive remote monitoring of equipment, accumulation of historical data, and analysis simply by connecting DX/IoT devices (IoT data collectors) to the PLC that controls the equipment. ■ Affordable pricing makes it easy to implement DX/IoT This IoT solution is priced to be easily adopted by medium and small enterprises, matching the need to start DX/IoT initiatives. ■ Use only the necessary functions from a wide range of features Customers can select features according to their needs. This means you can use only the necessary functions, minimizing costs associated with DX/IoT implementation. ■ Application features packed with manufacturer technology The application covers not only equipment monitoring and visualization but also predictive maintenance and analysis/improvement activities according to usage. ■ Cloud-based for "factory monitoring anytime, anywhere" With cloud technology, rapid response preparation and actions can be taken in the event of trouble, allowing for quick information sharing among all stakeholders. ■ We provide solutions to prevent equipment from stopping the factory Dangerous signs from equipment are alarmed, enabling predictive and preventive maintenance. Even if equipment does stop, rapid response is possible.

- Company:新東工業

- Price:Less than 10,000 yen

![Easy implementation to visualize the history of factory equipment [Equipment Operation Monitor]](https://image.mono.ipros.com/public/product/image/f67/2000684169/IPROS12116182585032515707.jpeg?w=280&h=280)